Blog

The Future of Manufacturing: The Role of CNC Mills Like JVC’s Haas VF-5 in Industry 4.0

The world of manufacturing is evolving faster than ever, with the pace of new technologies transforming how things are made year to year. One of the driving forces behind this revolution is Industry 4.0, which focuses on the smart integration of machines, data, and automation. At JVC Precision, our recent acquisition of a brand-spanking new Haas VF-5 Mill is at the heart of this transformation. The Haas VF-5 plays a crucial role in helping us stay ahead of the curve.

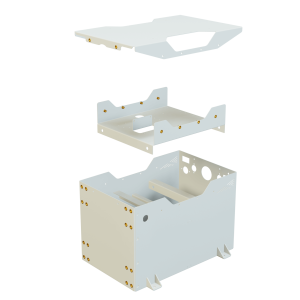

Design Consideration for Battery Box Fabrication

Battery boxes are essential in ensuring the safety, performance, and longevity of energy storage units and battery systems. These protective enclosures are designed to securely house one or more batteries in a purpose-built container. They have various applications, including backup battery storage units, exchangeable packs for electric vehicles, battery-powered industrial equipment like electric forklifts, and solar power storage systems. Due to their critical role, battery boxes must be designed with meticulous attention to various factors. Here are things to consider:

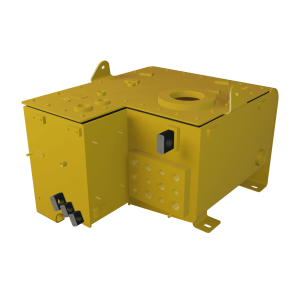

Overcoming Challenges With Fabricated Hydraulic Tanks

Click to Expand Fabricated hydraulic tanks are essential components in heavy equipment for mining, agriculture, forestry, and construction industries. They are mostly utilized in closed-loop systems for storing hydraulic oil. This accumulated liquid is then used to power the pump and drive various systems on the equipment, like cylinders and motors. Customized hydraulic tanks are preferred over off-the-shelf options in heavy equipment due to specific design constraints. For instance, the design envelope requires tailor-made tanks that fit within limited spaces

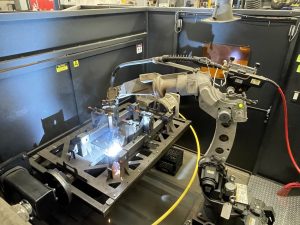

How To Determine if a Part Can Benefit From Robotic Welding

Robotic welding is a manufacturing process where a mechanized robotic arm is fitted with weld equipment (typically a MIG welding gun) and is programmed to follow a defined path to create a weld joint between two parts which are securely fixtured in a known location. This is a great way to automate a process which was traditionally very manual. It is widely used in the automotive, aerospace, and construction industries due to its precision and efficiency. In this article, we

Controlling Carbon and Laser Cutting

Click to Expand Laser cutting is a precise and efficient method for cutting materials using a high-powered laser beam. It directs the lights energy onto the surface, which melts or vaporizes it, creating a clean and accurate cut. This technology is widely used in the manufacturing, aerospace, and automotive industries for its ability to cut intricate shapes with minimal waste. The heat from the laser combined with the atmospheric oxygen creates an oxide or scale on the cut edge’s surface.

Design Considerations for CNC Press Brake Forming

Click to Expand Computer numerical control (CNC) press brake forming is a manufacturing method where sheet metal is bent and formed into desired shapes. It utilizes a die and v-block arrangement to exert force on the piece, resulting in bends at precise angles and positions. This method is particularly valuable in fabricating various products, including automotive components and intricate architectural elements. Press brake forming is used primarily in metal fabrication where the part quantity and complexity don’t warrant investment tooling