Products

Tanks

JVC Precision is a supplier of custom fabricated tanks and tank assemblies for use in non-pressure applications including diesel fuel, hydraulic oil, water tanks, overflow tanks and oil tanks. Our capabilities include Design, CNC Laser Cutting, Press Brake Forming, Welding, Robotic Welding, Finishing, Grinding and Assembly. We can provide complete tank assemblies including custom distribution blocks, vents, level indicators, connection ports, drains, filters, water separators and mounting brackets. We also provide custom finishing including chemical resistant coatings and epoxy paint.

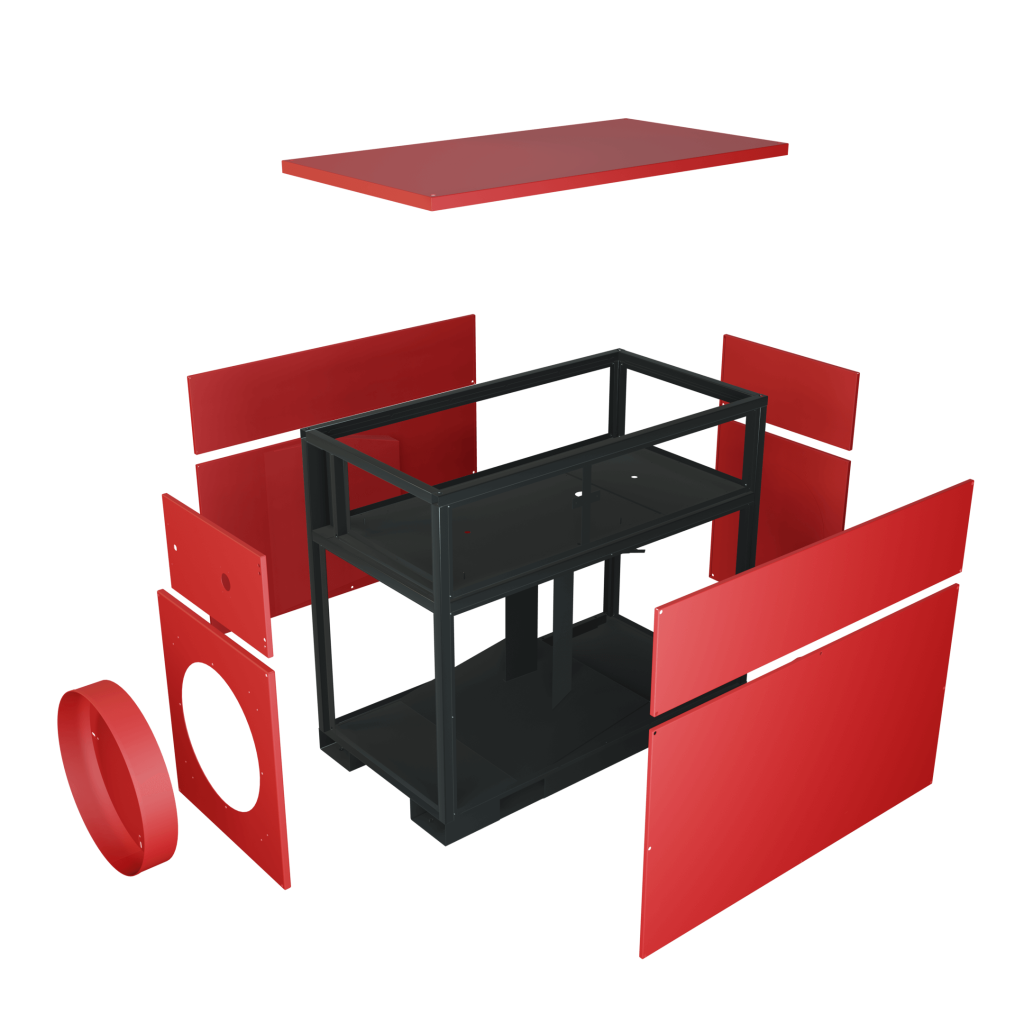

Boxes, Enclosures & Cabinets

JVC Precision is a supplier of custom boxes, enclosures and containers including battery boxes, electrical enclosures, cabinets and containers in stainless steel, aluminum and mild steel. Our capabilities include design engineering, CNC Laser Cutting, CNC Press Brake Forming, Welding, Robotic Welding, Grinding, Finishing and Assembly. We can provide complete solutions including grounding studs, NEMA rated, DIN Rails, Door latches and hinges, connection ports and mounting brackets. We have experience in specialty coatings including dielectric paints, paint masking, chemical resistant coatings, electrical isolation an insulation.

Covers & Guarding

JVC Precision is a supplier of custom covers, guards and panels manufactured in stainless steel, aluminum and mild steel. Products range from equipment guarding, panels and panel assemblies for work cells and automation cells and covers for industrial equipment. Our capibilities include design engineering, CNC Laser Cutting, CNC Press Brake Forming, Welding, Robotic Welding, Grinding, Finishing and Assembly. We can provide finished assemblies including access doors, windows and mounting brackets for sensors. We offer complete finishing solutions including powder coating, galvanizing and zinc plating.

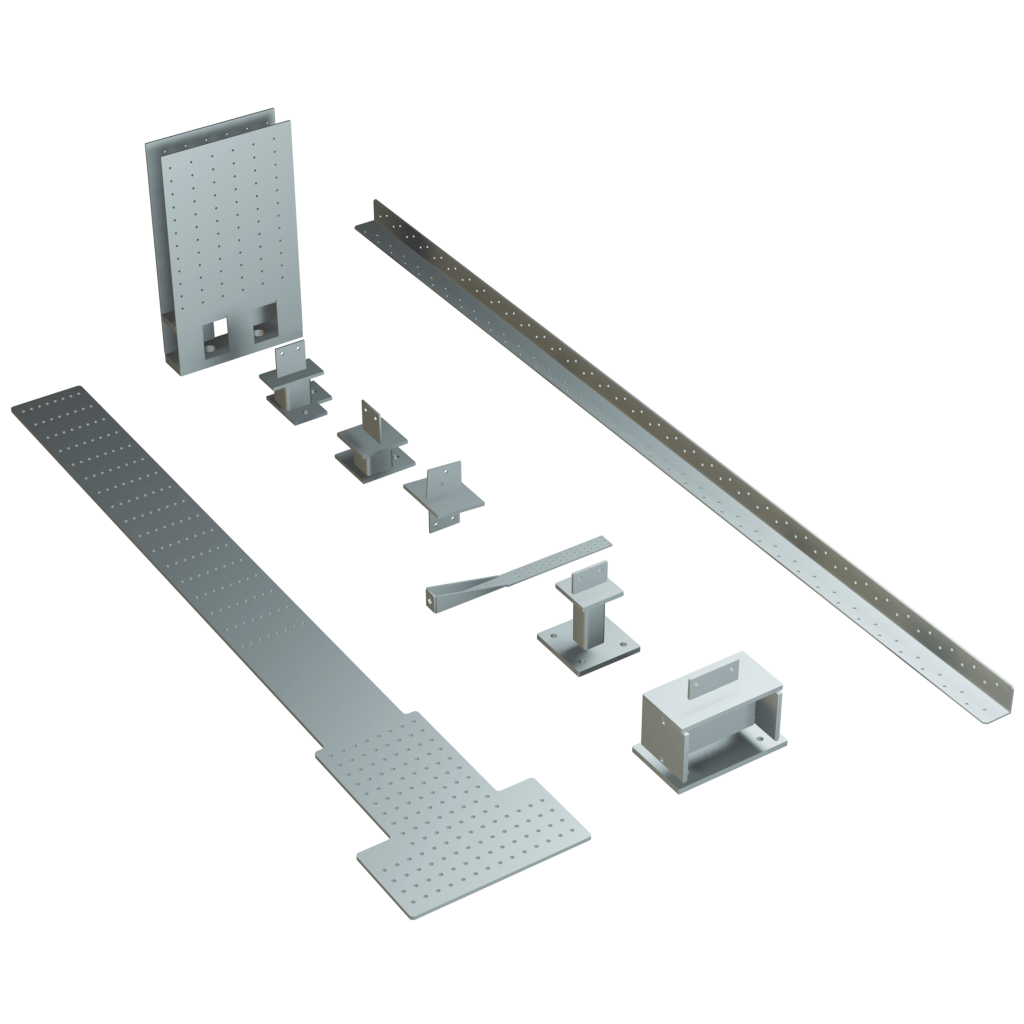

Custom Connections & Brackets

JVC Precision is a supplier of custom connections, brackets and plates in mild steel, stainless steel and aluminum. Product uses include structural connections for wood framed buildings, mass timber construction and CLT (Cross Laminated Timber) construction including base plates, ledger connectors, beam hangers, column base plates and connectors and knife plates. Manufacturing capibilities include CNC Laser Cutting, Sawing, Press Brake Forming, Hole Drilling, Welding and robotic welding. Finishing options include primed, powder coated, hot dip galvanized and epoxy painted.

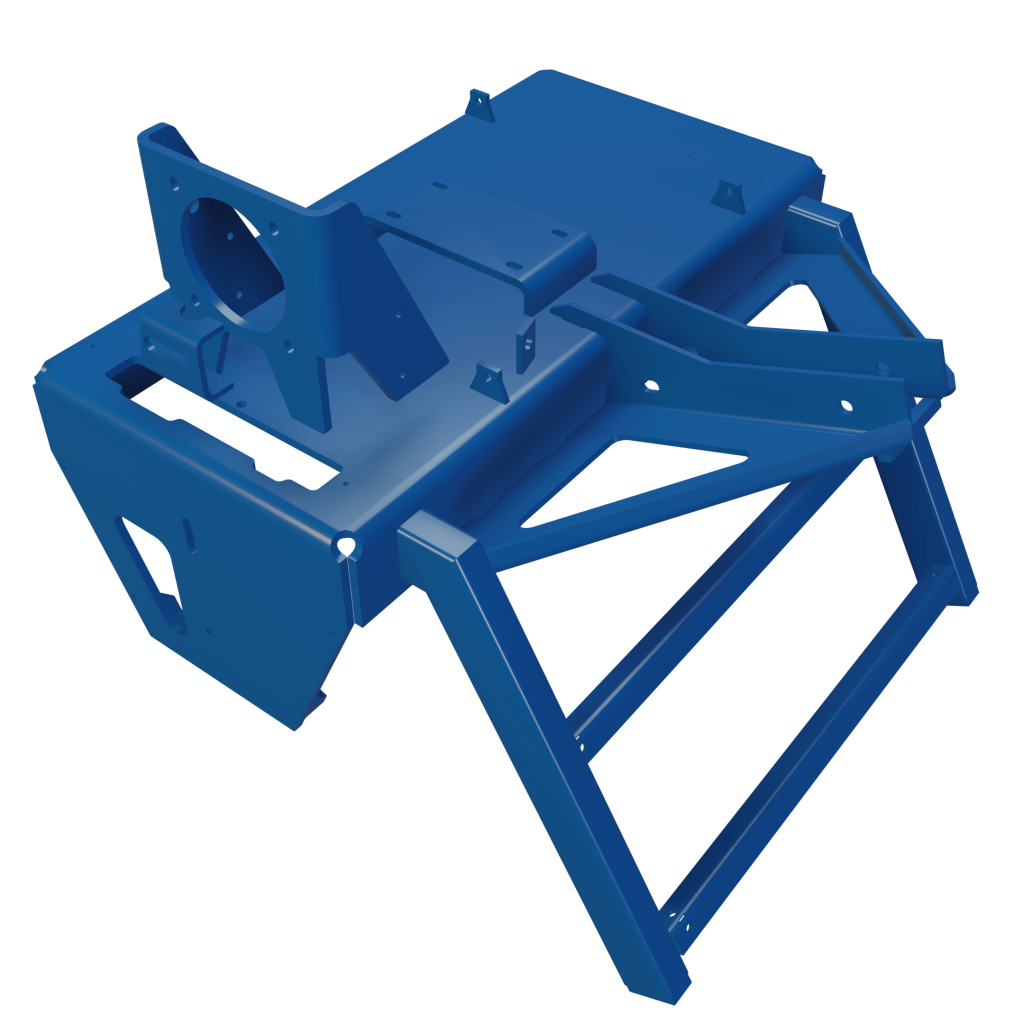

Specialty Vehicle Components

JVC Precision is a supplier of specialty vehicle components and assemblies in stainless steel, aluminum and mild steel. Components include frame weldments, bumpers, fenders, fuel and hydraulic tanks, brackets, engine housings, cab enclosures, exhaust guards, side steps, skid plates, motor mounts, suspension mounts, transmission mounts amongst others. Assemblies include man carrier bodies, ROPS/FOPS canopies, flat decks, mechanics truck bodies, and utility truck bodies. Our capibilities include design engineering, CNC Laser Cutting, CNC Press Brake Forming, Welding, Robotic Welding, Grinding, Finishing and Assembly. We can provide complete solutions including assembly and finishing. We have experience in specialty coatings including epoxy paint, powder coating and galvanizing.

Custom Weldments

JVC Precision provides Contract Manufacturing services for fabricated sheet metal weldments and assemblies in mild steel, stainless steel and aluminum. Our capibilities include Design Engineering, CNC Laser Cutting, Press Brake Forming, Welding, Robotic Welding, Finishing, Grinding and Assembly. We can provide services such as mechanical assembly, custom finishing and custom packaging.

Metal Fabrication Process: A Step-By-Step Overview

Metal fabrication is the process of transforming raw metal materials into finished products that meet specific design and engineering requirements. It involves various techniques, including cutting, shaping, assembling, and finishing. It is a critical aspect of manufacturing and is utilized in multiple sectors, such as automotive, aerospace, mining, and construction.

At JVC Precision, we take pride in our legacy as a leading metal component manufacturer serving industrial OEMs since 2006. We specialize in designing and manufacturing metal components and assemblies that precisely align with your specifications. The metal fabrication process can vary depending on the specific requirements of the project, but it generally includes the following key steps:

Design

The manufacturer’s design team works closely with the customer to analyze project requirements, manufacturing approaches, and potential improvements. Using computer-aided design (CAD) software, they produce detailed designs that serve as the blueprint for the fabrication process.

Material Selection

Metal fabrication works with various metals, including steel, aluminum, copper, and stainless steel. The choice of material is crucial and depends on factors such as strength requirements, corrosion resistance, and the intended application of the final product.

Prototyping

Prototyping offers a tangible preview of the final product. Rapid prototypes are created as the first step in preparing for a larger production run. First-off units are inspected for conformance to the customers requirements, allowing the customer and design team to make necessary adjustments or improvements before proceeding to full-scale production.

Programming

Once the design is finalized, it is translated into precise programming for computer-controlled machines. Automated cutting, forming and robotic welding require precise programming to ensure the accurate execution of the design.

Fabrication

The duration of fabrication varies based on factors such as part complexity, involved processes, and shop demand. It may include cutting, folding, machining, welding, and other techniques to shape and form the metal into the desired product.

Finishing

Following the completion of fabrication, the product undergoes finishing processes. This step focuses on refining surfaces and edges to meet quality standards. Various coating options, including powder coating, may also be applied to enhance durability and aesthetics.

Assembly

Some fabrication providers like JVC Precision extend their offerings to include assembly. This phase involves bringing together fabricated components via welding or electrical integrations when necessary. Assembly ensures that the final product is a fully functional and cohesive unit.

Quality Metal Products From JVC Precision

At JVC Precision, we take pride in delivering high-quality metal products crafted with precision and expertise. Our diverse range of products caters to various industries, offering solutions that meet and exceed your expectations. Explore our product lineup below:

Tanks

Our tanks are engineered for non-pressure applications and designed to cater to diverse needs, including diesel fuel, hydraulic oil, water storage, overflow, and oil containment. We also provide comprehensive assemblies, such as custom distribution blocks, vents, level indicators, connection ports, drains, filters, water separators, and mounting brackets. Moreover, your tanks receive the finishing touch they deserve, with options like chemical-resistant coatings and epoxy paint to ensure longevity and protection.

Boxes, Enclosures & Cabinets

JVC Precision specializes in creating solutions that provide secure housings for various applications, including battery boxes, electrical enclosures, and cabinets. Our products are available in stainless steel, aluminum, and mild steel. We also offer grounding studs, NEMA-rated options, DIN Rails, door latches and hinges, connection ports, and mounting brackets, providing comprehensive solutions.

Covers & Guarding

Our products range from equipment guarding and panels to covers for industrial equipment. They can be manufactured in stainless steel, aluminum, and mild steel. Our offerings include finished assemblies with access doors, windows, and mounting brackets for sensors, providing a comprehensive solution for your industrial needs. We also offer a range of finishing options — including powder coating, galvanizing, and zinc plating — ensuring that our covers and guards are durable and corrosion-resistant.

Custom Connections & Brackets

JVC Precision excels in providing custom connections, brackets, and plates designed to enhance structural integrity in various applications. Our products — crafted in mild steel, stainless steel, and aluminum — serve diverse purposes. This includes structural connections for wood-framed buildings, mass timber, and cross-laminated timber (CLT) construction. Choose from various finishing options: primed, powder-coated, hot-dip galvanized, and epoxy-painted.

Specialty Vehicle Components

As a trusted supplier of specialty vehicle components, JVC Precision delivers a comprehensive range of stainless steel, aluminum, and mild steel products. Our components — including frame weldments, bumpers, fenders, hydraulic tanks, and various other specialized parts — catering to the unique demands of vehicles across diverse industries. In addition, we offer complete vehicle body assemblies, such as man carrier bodies, ROPS/FOPS canopies, flat decks, mechanics truck bodies, and utility truck bodies.

Custom Weldments

JVC Precision provides top-notch contract manufacturing services for fabricated sheet metal weldments and assemblies in mild steel, stainless steel, and aluminum. Beyond fabrication, we provide mechanical assembly services, ensuring your custom weldments are ready for integration into larger systems.

Why Choose JVC Precision for Your Projects

At JVC Precision, our commitment to excellence and proven track record set us apart as the preferred choice for your metal fabrication needs. Here’s why partnering with us ensures your projects are in capable hands:

Experience Across Canada’s Industries

Established in 2006, JVC Precision has a rich history of providing metal-fabricated components and assemblies to diverse industries across Canada. Our facility is a hub of comprehensive metal fabrication services, providing design services and volume manufacturing products for the mining, forestry, construction, and manufacturing businesses.

Comprehensive Metal Fabrication

JVC Precision offers a complete range of services covering the entire product development life cycle. From full-service design engineering and rapid prototyping to advanced laser cutting,precision CNC brake press forming and robotic welding, we provide a seamless approach to metal fabrication.

Collaborative Approach for Innovative Solutions

We believe in the power of collaboration. Understanding your needs allows us to leverage our extensive experience, offering innovative solutions that solve problems and enhance project outcomes. In addition, our structured processes are designed to provide you with a seamless customer experience. From initial collaboration to the final delivery, we prioritize transparency, communication, and customer satisfaction.

Exceptional Talent and Craftsmanship

JVC Precision takes pride in hiring only the best talent, ensuring that our team is highly skilled, experienced, and dedicated. From engineers and fabricators to welders and assemblers, each individual brings a unique expertise that collectively elevates our capabilities. This diversity ensures that we can tackle a wide range of projects and deliver products that meet and exceed expectations.

State-Of-The-Art Equipment and Facility

At JVC Precision, we maintain a cutting-edge facility with state-of-the-art equipment that meets and exceeds industry standards. Our advanced technology includes the Mitsubishi GX Series CNC Fiber Laser for precise laser cutting and Amada CNC Press Brakes for tight tolerance bends. We also offer full-service design engineering with top-notch 3D CAD software, ensuring clear objectives before production.

JVC Precision: Your #1 Source for Top-Notch Metal Products

If you are looking for a trusted partner to elevate your metal fabrication projects, look no further than JVC Precision! We are committed to delivering high-quality metal products crafted by professionals. Our facility is fully equipped with advanced software, machines, technology, and equipment to provide top-notch solutions. Get a full-service experience, ensuring the seamless production and assembly of components into a fully functional, cohesive unit!

Contact us to learn more about our offerings, or request a quote today to get started.